Every piece of our socks & hosiery items are made in Saga Pref. (Japan) very carefully & wholeheartedly for our customers’ comfort.

As a Top Specialist in in Manufacturing Socks & Inners, We Perform All the Procedures from Planning, Designing and Knitting to Final Inspection at our Full Responsibility.

-Skills Production Technology

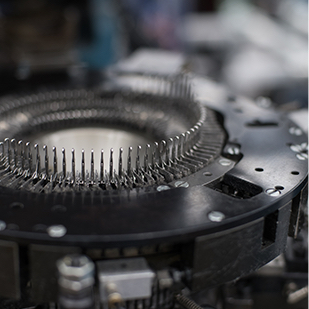

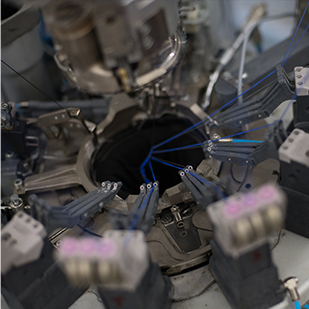

Technology Brushed-up Over a Century

Based on our own over-a-century technology & most advanced facilities, our hosiery production is oriented for consumers’ beauty and health. We’re also ready for small-lot production of diversified product types in response to the diversification of consumers’ needs. Sticking to domestic production and pursuing the high function & high quality of the products, we’re always oriented to make distinctive products for consumers.

-Steps Manufacturing Process

Reliable Products via Integrated Production

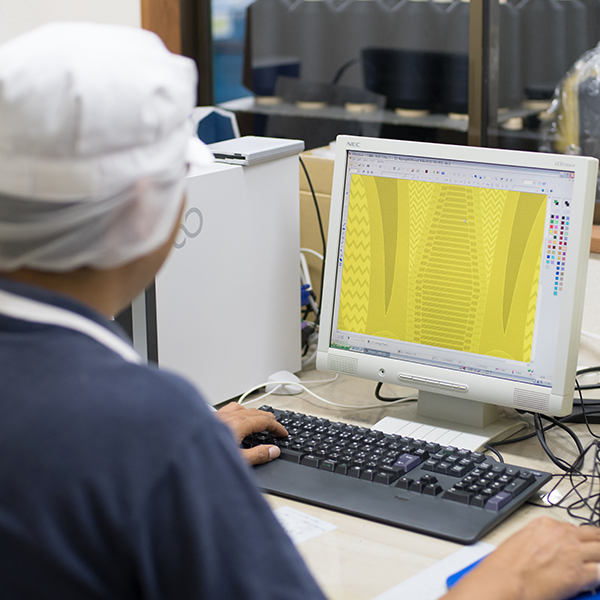

Our production is based on the integrated manufacturing. In order to deliver “Product Reliability& Safety” and “Comfort” to our customers, the whole manufacturing process from Designing and Knitting to Final Needle Detection and Shipment is carefully performed and managed under our own thorough and integrated quality control.

All the production data is managed collectively by our computers for more production efficiency.

※For some items, their production process is shortened.

-Products Our Product Lineup

-Company Corporate Profile

This year of 2019 marks our 100th anniversary since our business foundation.

Just like in the past, we are passionately pursuing the making of higher-value products at the most optimal manufacturing places (domestic or abroad). By doing so, we proudly continue to make innovative products of vide variety for consumers’ more pleasure.

As an enterprise in the domestic secondary industry, we are highly proud of our own 100th anniversary. During Japan’s high economic growth in the past, the domestic secondary industry made a great progress, but this industry has become very sluggish because of rapid economic globalization seen in the recent some ten years. During such upheavals of the textile/apparel industry we belong to, we’ve made the best use of our own technology and expertise, which we have piled up so far, and successfully managed to react to such big change by sticking to our business policy of creating high-value-added products at the most optimal places of production.

All our products touch the skins of their users. So our products must be human-body friendly and highest in quality & safety, which is the necessary requirements Japanese makers like us can fully satisfy. In this aging society with fewer children, consumers have become more oriented for health and higher-value products. Amid these situations, we believe our highly functional products really satisfy our users and contribute more to such society now.

Product quality must be always good, needless to say. With this in mind, we’re aiming to focus more on strengthening our own business capabilities to create more advanced products and to perfectly satisfy consumers’ needs. This is to create further higher values to our products in the current products-saturated society. Thus, we’d like to remain as a shining manufacturer with fundamental strength.

We proudly, as a Japanese maker, continue to make innovative products for consumers’ more comfort and pleasure. By doing so, we’d like to make a great progress together with all our customers. We sincerely appreciate for your further patronage toward us also from now on, just like in the past. Thank you.

Takuji Iida President

Corporate Profile

| Corporate Name | IIDA HOSIERY CO. LTD. |

|---|---|

| Business Locations | 1619, Yamaguchi, Kohoku-machi, Kishima, Saga Pref. 849-0501, Japan TEL:+81-952-86-3211 FAX:+81-952-86-3214 |

| Founded on | August 10, 1919 |

| Established on | October 20, 1948 |

| Representative | Takuji Iida (Mr.), President |

| Capital | 85 million yen. |

| Business Line | Manufacture & Sales of Clothing |

| Major Product Line | Hosiery (Socks, Tights, Spats, Supporters, Inners, etc.) |

Corporate History

| 1919 | IIDA HOSIERY was founded. |

|---|---|

| 1948 | IIDA HOSIERY CO. LTD. was established (in Gose City, Nara Pref.). |

| 1964 | Advanced to Kyushu and established Saga Factory. This was in response to the invitation of companies by Saga Pref. for developing its coalmine areas. |

| 1971 | Established another factory in Kashima City, Saga Pref. (Kashima Factory) |

| 1995 | Newly Built and Established Saga Factory |

| 2002 | Introduced the training system for Non-Japanese employees (trainees from Vietnam). |

| 2003 | Increased its capital into 85 million yen. |

| 2005 | Kashima Factory was merged with Saga Factory.Acquired ISO 9001. |

| 2006 | Acquired the license as Medical Device Manufacturer. |

| 2007 | Developed its Direct Sales Division into an independent enterprise named “ifan Co. Ltd.” |

| 2012 | Business operations of “ifan Co. Ltd.” were merged into IIDA HOSIERY CO. LTD. |